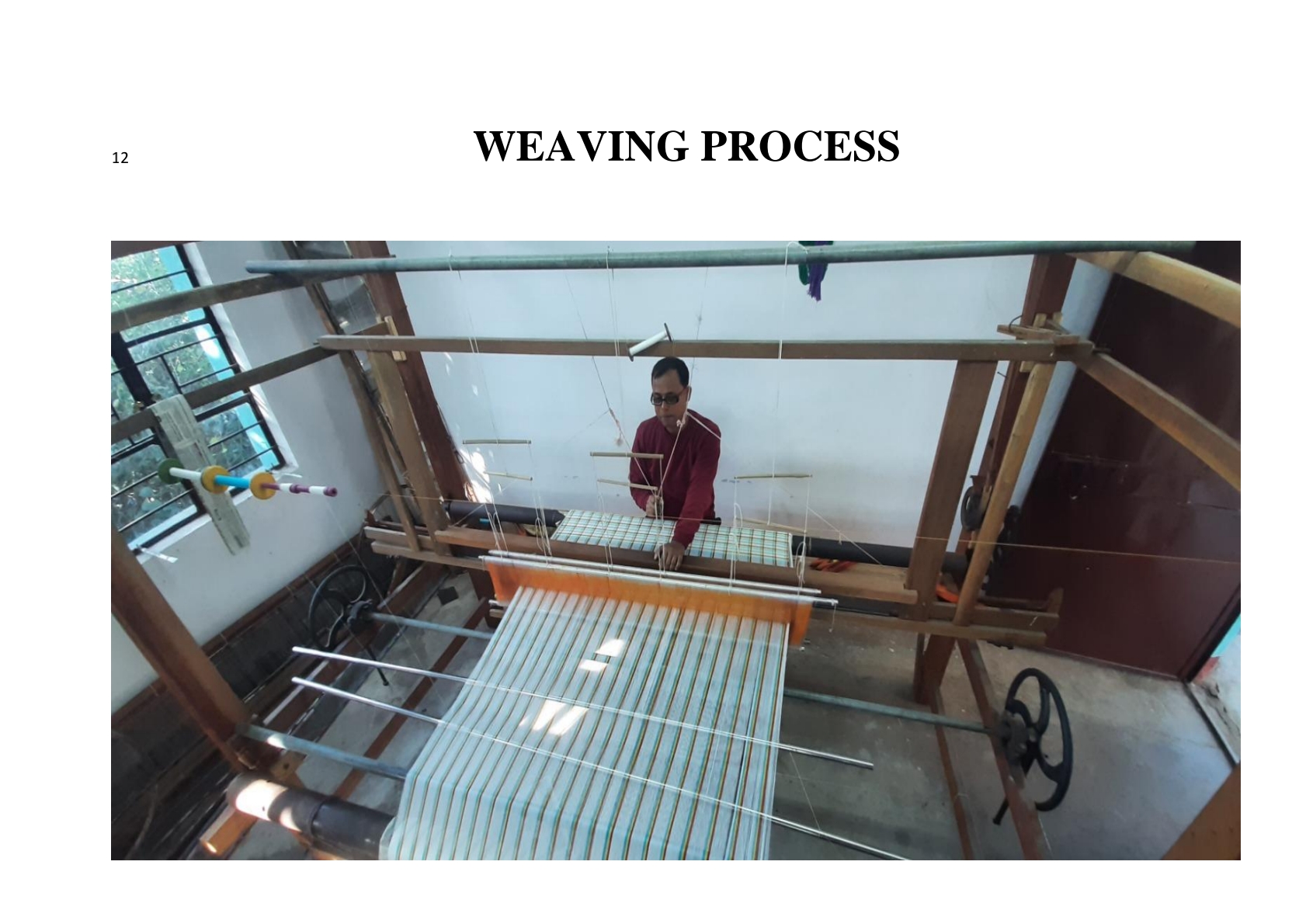

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft . The method in which these threads are inter-woven affects the characteristics of the cloth. Cloth is usually woven on a Handloom, device that holds the warp threads in place while filling threads are woven through them. A fabric band which meets this definition of cloth (warp threads with a weft thread winding between) can also be made using other methods, including tablet weaving, Jacquard Weaving, back strap loom, or other techniques without looms. The way the warp and filling threads interlace with each other is called the weave.HHA

Block Printing ( Manual)

Block printing is the process of printing patterns on Fabrics , usually on linen, cotton or silk, by means of incised wooden blocks. It is the earliest, simplest and slowest of all methods of textile printing. Block printing by hand is a slow process. It is, however, capable of yielding highly artistic results, some of which are unobtainable by any other method. Woodblocks for Fabric printing may be made of box, lime, holly, sycamore, plane or pear wood, the latter three being most generally employed. They vary in size considerably, but must always be between two and three inches thick, otherwise they are liable to warping, which is additionally guarded against by backing the wood chosen with two or more pieces of cheaper wood, such as deal or pine. The several pieces or blocks are tongued and grooved to fit each other, and are then securely glued together, under pressure, into one solid block with the grain of each alternate piece running in a different direction. The block is carefully pressed on the sieve, and as the different parts of its pattern fall on sieve, each takes up a certain colour that it transfers to the cloth in the usual way. By this method of tobying from two to six colours may be printed at one operation, but it is only applicable to patterns where the different coloured objects are placed at some small distance apart, and that, therefore, it is of but limited application.

Dyeing Technique

Dyeing is the application of color dyes or pigments on textile materials such as fibers, yarns, and fabrics with the objective of achieving color with desired fastness. Dyeing is normally done in a special solution containing color dyes and particular chemical material. Dye molecules are fixed to the fiber by absorption, diffusion, or bonding with temperature and time being key controlling factors. The common dyeing process of cotton yarn with Vate Dye, Direct dye, Reactive Dye at package form is as follows:

- The raw yarn is wound on a spring tube to achieve a package suitable for dye penetration.

- These softened packages are loaded on a dyeing carrier’s spindle one on another.

- The packages are pressed up to a desired height to achieve suitable density of packing.

- The carrier is loaded on the dyeing machine and the yarn is dyed.

- After dyeing, the packages are unloaded from the carrier into a trolley.

- Now the trolley is taken to hydro extractor where water is removed.

- The packages are hydro extracted to remove the maximum amount of water leaving the desired colour into raw yarn.